Back in January I had the privilege to visit the Harlick factory in San Carlos, CA., for the first time. I’ve had several pairs of boots from Harlick, but previously I’d been fitted locally. This time I got to tour the factory and meet the staff. I met Ginger, Phil, and Phil’s sons and other workers on the floor.

Here’s their waiting room with signed photos of some the many famous skaters who have worn their boots:

And photos of the long hand crafting process of making their boots:

Phil showed me around the factory floor which had several types of big, black industrial sewing machines, sanding machines, glue pots, their collection of lasts, and lots of skates in various stages of production.

I wish I’d gotten permission to show you the workers hammering, sanding, and sewing away. Shoes are made by hand all over the world, but it’s amazing to see this fourth generation family business still in operation so close to San Francisco. Phil explained some of the processes to me. I’m getting one of their newer options, a carbon fiber sole, on my new skates, so he showed me how the carbon fiber is glued on to the sole in layers.

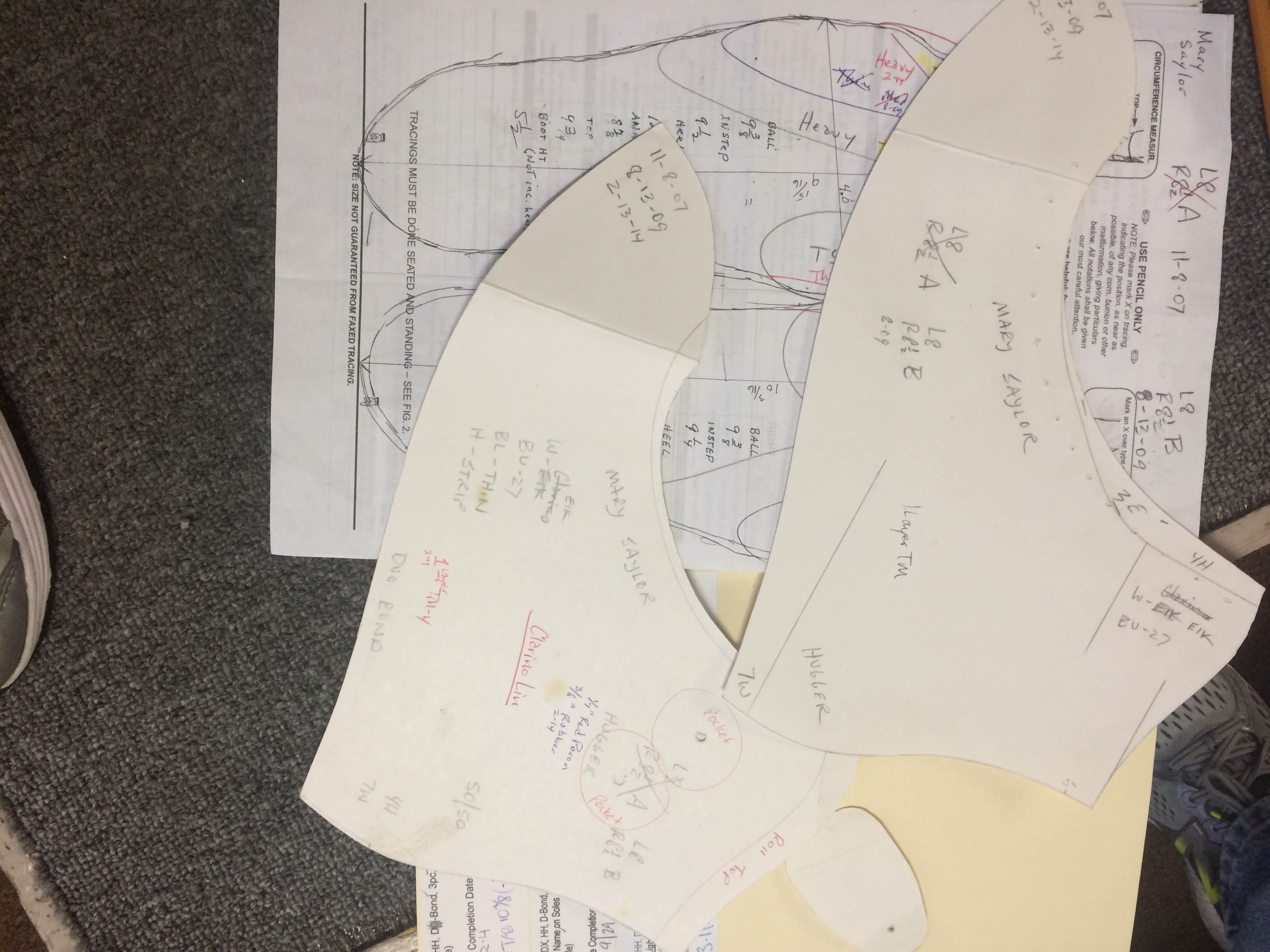

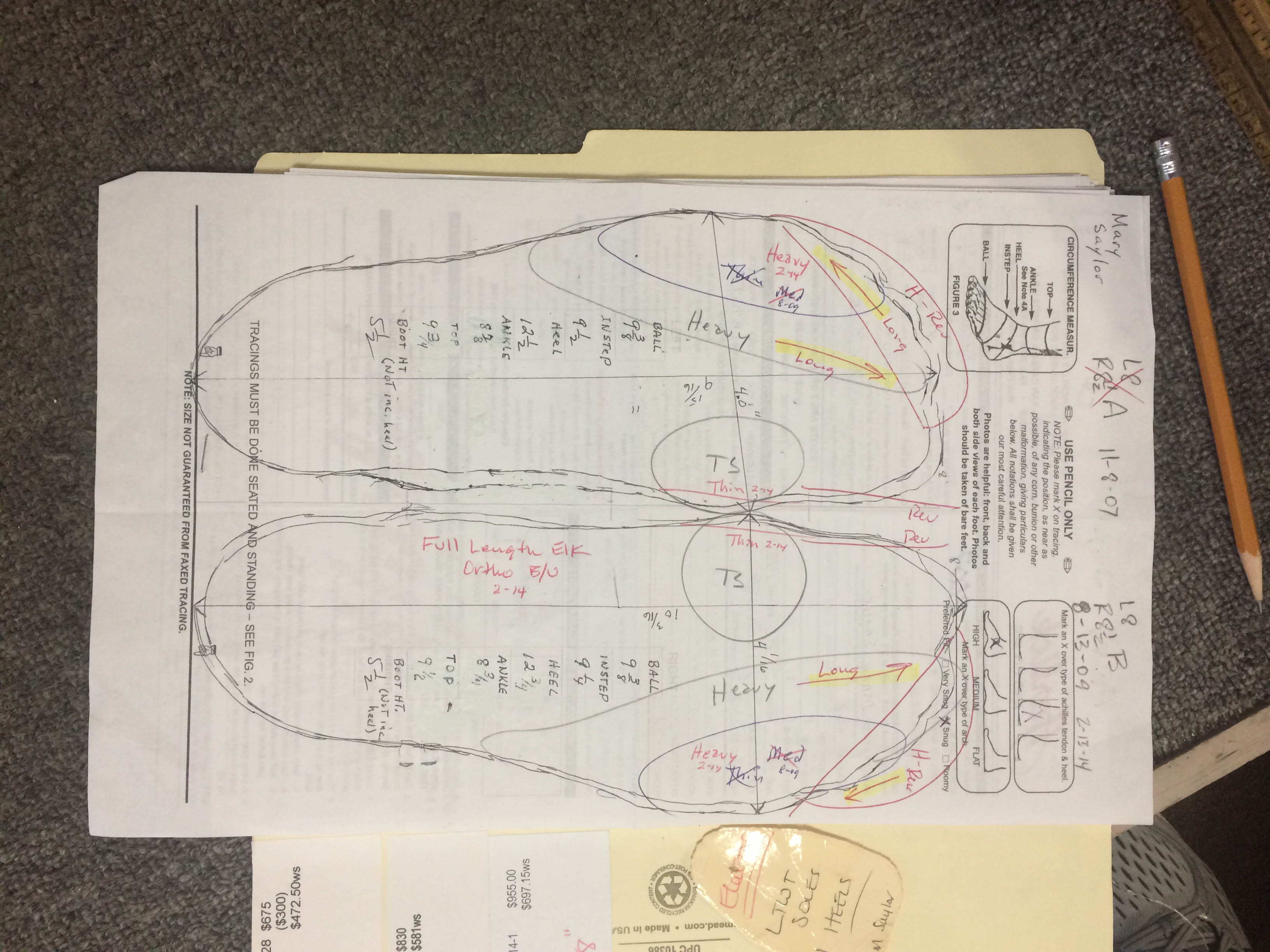

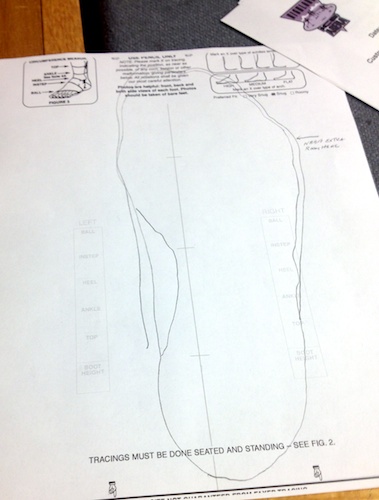

Then it was time for Phil to fit me for the skates. He got out my file with tracings of my feet and the pattern they’d made for constructing my previous skates. Harlick keeps a file on each of their skaters and the file is kept at least 10 years. The tracings have notes about each irregularity of my foot that needs to be accommodated when making the boot. Phil carefully measured my feet in various dimensions, sitting and standing.

In my case, Phil told me, my feet are different enough from each other that they make my boots using a different last for each foot. They build up the last to more closely resemble my foot and then make the skate around it.

I hadn’t yet decided what kind of blade I wanted on my new skates, so Harlick couldn’t start making my boot right away. The sole is shaped to fit the blades from a specific manufacturer.

On my way out I took another look at some of the skaters’ photos. I paused by Rudy Galindo’s photo and Phil told me that he and other Harlick staff got to watch Rudy win Nationals in nearby San Carlos wearing their skates. Here’s Rudy’s photo:

I probably couldn’t do better than to end with Rudy’s epic Black Swan program at the 1996 Nationals. If you aren’t crying by the end of it you are a more stoic person than I am:

{ 8 comments… read them below or add one }

Such cool photos of the Harlick factory, Mary! I love that they custom make boots for skaters and keep their measurements and tracings on file. Thanks for sharing this inside-the-factory tour with us!

Eva at Eva Bakes recently posted..S’mores skillet cookie

Thanks! Harlick is a special place, the real deal. And my feet are odd enough that I need them!

Wow, that’s amazing. I’ve never tried Harlick’s but some of the really terrific skaters I know swear by them. And the carbon fiber sole sounds really cool–what does it do for the fit of the skate? I love that Rudy Galindo program–thanks for the heart-warming trip back down memory lane!!!

Jo recently posted..My free leg is my friend

It makes the boot lighter and more rigid, eliminating the need for the steel shank. Without the shank the boot is more comfortable.

Lucky you! I’d be chomping at the bit to tour a place like that! Oh yes, I well remember Rudy’s iconic performance. I’m excited for you to get your new skates!

Marcia recently posted..Injury Update and Some Goodness Too

I’m glad we share a love for that performance! And for factory tours! I’m very excited about the new skates too.

Fascinating! Thank you for the virtual tour. I’d love to do that, too. Hope it won’t be long before you get your beautiful new skates. I got measured for Harlicks but ended up sticking with Riedells. My fitter said I had either Harlick or Riedell feet. (I could have gotten stock Harlicks). Some day I want a pair of Harlicks with pink kitty cutouts.

Oh yeah! I love the cutouts that people get on their Harlicks, would love to see you with a pink kitty one!